SHIPE has solidly carried out "5S" lean factory management work

publishdate:2022-01-25 views:2141

PHASE REPORT (Ⅰ)

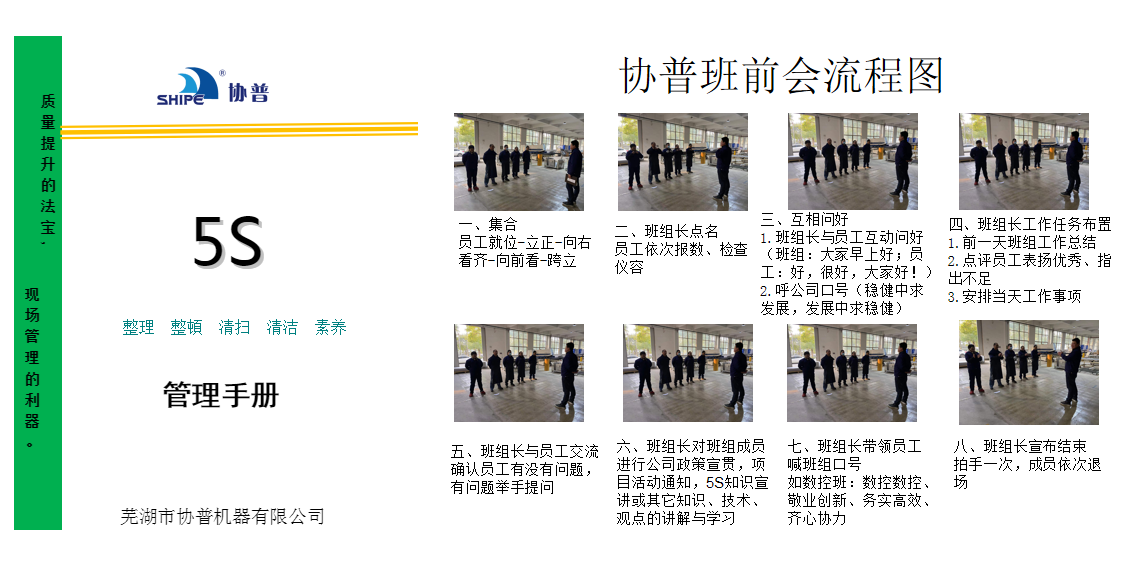

In the expectation of the whole factory staff, SHIPE welcomed the first round of coaching from Mr. Ho Hongqi, a senior consultant of "5S" lean factory management of VMTA, on January 7, 2022. The "5S" lean factory management is expected to lasted for total 7 months and will be experienced 17 rounds of on-site counseling and rectification, thus our company forming a normalized management and operation mechanism of ourselves. All departments and teams of the company responded positively, organized carefully, and effectively promoted the detailed implementation of the "5S" lean on-site management work, and achieved initial results after the first round of counseling.

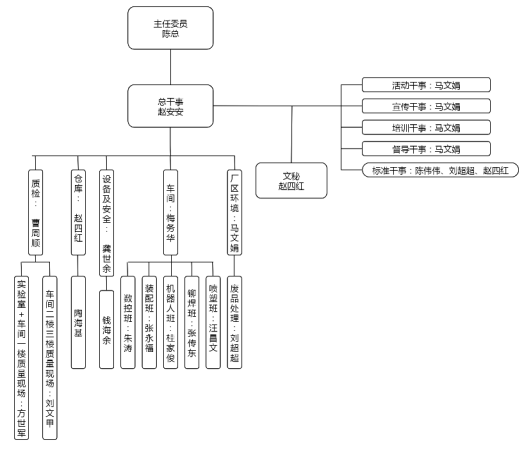

In order to ensure the smooth progress of related lean improvement work, our company has established a "5S Committee", which has set up an executive bureau system, which is responsible for the organization, coordination, implementation, publicity and supervision of “5S” lean actions. In order to clarify the division of responsibilities, in addition to the on-site guidance of VMTA, the implementation committee held a "5S" mobilization meeting, established a "5S" work exchange group, produced and issued a "5S" brochure, and collected "5S" activity slogans. It conveyed and implemented the company's commitment to improving the overall factory appearance and the relevant spirit of lean factory requirements, and carried out comprehensive mobilization and detailed deployment for the implementation of lean factory management actions, which deepened all SHIPE families understanding of "5S" work, and promoted the implementation of lean site management of good "5S" work experience and practice of learning and exchange.

This event has been actively recognized and cooperated by whole SHIPE staff since carried out, according to VMTA’s on-site instruction and staged correction plan, all leaders of each department and even each production team handling and managing by ourselves, and made a detail implementation plan of “on-site management action” based on each location situation. Our "5S Committee" also organizes on-site inspections of each team area, and timely puts forward rectification suggestions for hidden problems found in the inspection, and continues to promote improvement.

Actively participating in the on-site counseling of VMTA to further promote the "5S Lean Site Management Action" is a major event of SHIPE work plan in 2022. Improve the work efficiency, and make all efforts to contribute each team member to the new factory appearance of SHIPE by ourselves.